The case selected by the investigators was Daniel Silva"s, who had an accident at the age of 8, in which he lost his pointing and hearth fingers and atrophied his thumb and pinky with a machine in his father"s workshop of metal crafts and structure for security doors.

This circumstances motivated Christian Silva and Jhon Muñoz, professionals in mechatronic engineering from Universidad Nacional de Colombia, and an interdisciplinary team of professionals to think about how to reconstruct upper limbs with prosthesis at a low cost with technology and innovation.

The initial analysis evaluated the significant movement lost, the hypertrophy in some muscles and the weakened tissue in Danny"s hand. The diagnosis was evident, as well as the cosmetic need. The project Mechanical and cosmetic design of a partial hand prosthesis was, without any doubt, a process designed for the patient, for his needs, possibilities, residual capacities, and from his perceptions, feelings and desires.

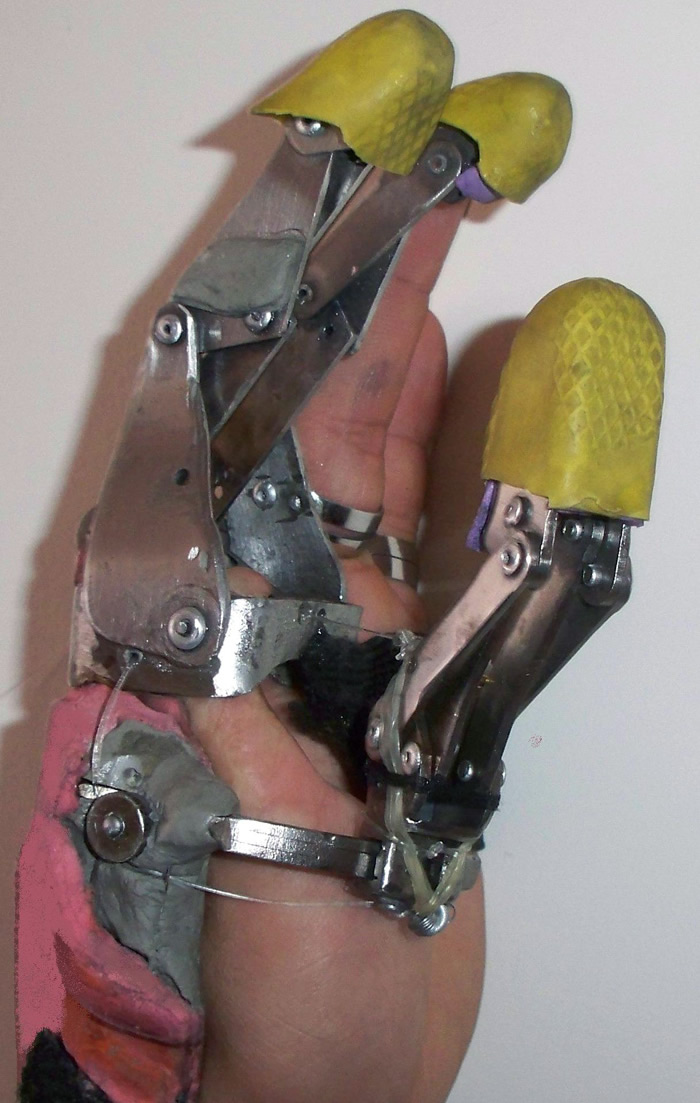

Different prototypes were built to finally obtain the definitive model that covered the patient"s needs. The first model was made with duracover, a cardboard-type material, which "helped testing if angles of the hand"s coverage were correct and if they would correspond to what you see in a finger," said Silva.

The second model was designed in acrylic, a material though to be more functional and applicable in this case due to its components. However, at the end, stainless steel was chosen. "The previous materials were not rigid enough to build a prosthesis that withstood the loads managed by a normal hand. Cardboard was used only to test the movements; acrylic was weak, and, at first, we though weight was going to be a problem with steel, however, at the end, we noticed steel was perfect", mentioned Muñoz.

In terms of esthetics, the model of prosthesis was improved through the application of the science that makes artificial limbs look real. "With this project, it was evident that both, the cosmetic aspect and the functionality, are equally important. The patient is always interested in the functionality and esthetics of the prosthesis," said Silva.

For Nancy Landinez, physiotherapist from Universidad Nacional de Colombia who was part of this project, prosthesis try to satisfy not only the functional need, but also the self-image need, the self-concept of body image and the sensation of how the patient feels in society, "knowing that in the end many people like Danny can perform an activity with his entire hand, independently of the capacity of movement, is a matter of feeling complete".

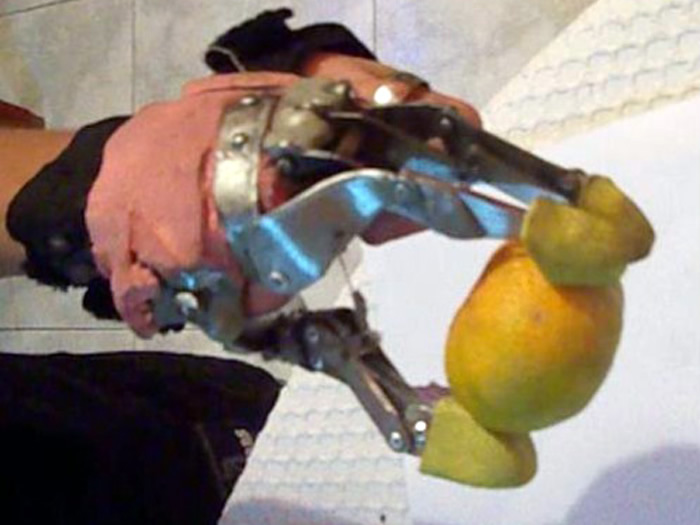

All prosthesis need a training and adaptation phase to be used. The time spent in the construction of the prosthesis and the training for Danny"s prosthesis was 3 months. "The idea was to obtain almost 100% of the hand"s functionality, even when it is difficult, in this project a 90% was achieved," explained Christian.

Among the benefits, the accessibility for the public, due to its low cost and its simplicity, are the most remarkable because it does not need to be controlled by a card, electricity or battery to function, since it is completely mechanical, that is to say, the prosthesis works with the movement of the hand itself to perform all the normal tasks.

Likewise, it is remarkable the work of the interdisciplinary team, the interaction of the members of Universidad Nacional de Colombia which were part of this project: engineering directed by Professor Diego Garzón, physiotherapy for controlling the organism and the work of engineers Silva and Muñoz, who were awarded at Otto de Greiff Awards, due to their excellence.

For Danny, who motivated this project, the result of the prosthesis was positive. The basic needs were fulfilled not only in the functionality, but also in its cosmetic part, which helped him not to be afraid of showing his hand in public. "He does not really care if he"s using the prosthesis or not, since he does not feel rejected or attacked", said Jhon.

The idea of these professionals from Universidad Nacional de Colombia is perfecting the prosthesis model, improving its mechanisms with a better esthetic and start new prosthesis for hands, arms, legs, etc. In addition, they want to contribute with both, the cosmetic and functional welfare, of those who need prosthesis for different reasons.

Correo Electrónico

Correo Electrónico

DNINFOA - SIA

DNINFOA - SIA

Bibliotecas

Bibliotecas

Convocatorias

Convocatorias

Identidad UNAL

Identidad UNAL