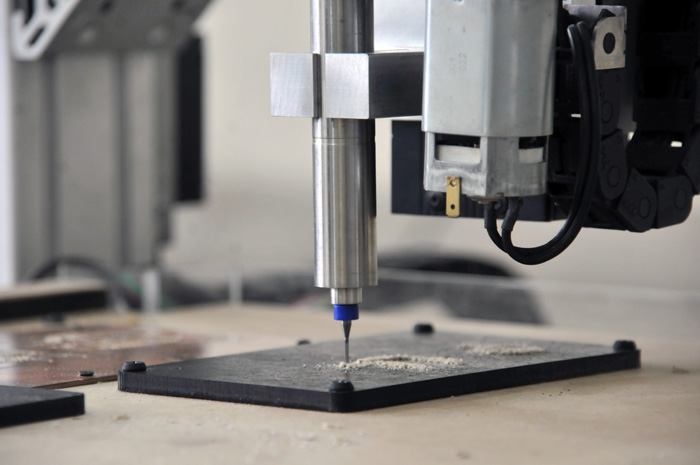

The machine that allows the modeling of pieces such as electronic cards used in the manufacturing of USB memories, or metal engraving by means of computer programming (machining), was designed by Aldemar Martín, electronic engineer of Universidad Nacional de Colombia.

Using magnetic levitation (displacement without friction), this high speed positioning system with lineal servomotor, as it is technically known, allows routing or modeling materials through abrasion or perforation with high speed, precision and quality.

"The machine is composed by three axes of work, moved by lineal engines, that reach speeds up to five meters per second, and accelerations five times higher than the gravity of the Earth. Besides, its autonomy of work, previously programmed with software, reaches millimetric accuracy levels," explained Julie Paternina, student of the Master in Industrial Machining of Universidad Nacional de Colombia.

However, the machine"s speed produces strong vibrations in its structure that, in some cases, can cause the rupture of cutting tools and feed materials.

"Vibrations produced by high speed machines are very strong and inconvenient since they can damage tools and materials, or even affect the quality of cuts. For this reason it is better to use it at soften speed profile," asserted Paternina.

Therefore, the student is studying the reduction of the impact generated when the machine"s speed changes by modifiying the software, so that the system can be adapted to laser cutting technologies and microfacturing.

Correo Electrónico

Correo Electrónico

DNINFOA - SIA

DNINFOA - SIA

Bibliotecas

Bibliotecas

Convocatorias

Convocatorias

Identidad UNAL

Identidad UNAL