Members of the Bioprocesses and Reactive Flows Research Group from Universidad Nacional de Colombia in Medellin worked on the innovation.

The group from Universidad Nacional de Colombia was supported by the Colombian Banana Association (Augura), which provided the residues for the development of the investigation.

What the researchers did was taking samples from steams; some of them just cut from the banana plant and others weeks or months old. The objective was to evaluate the change in the composition of the shoots and the ripening of the banana, as well as the sugar and starch contents.

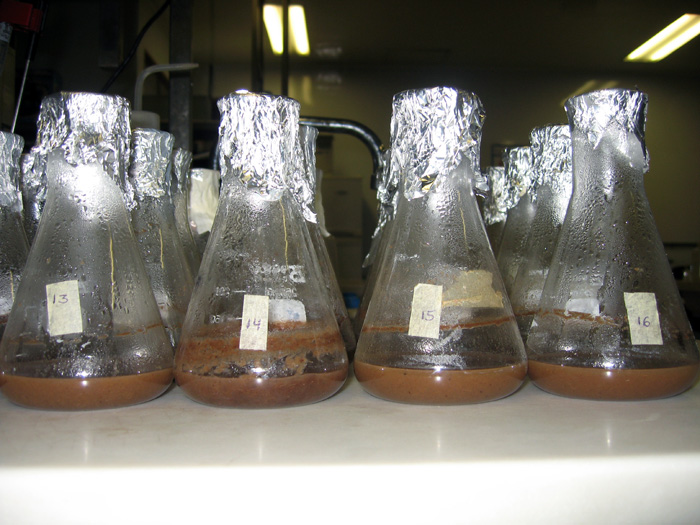

During the analysis, it was noticed that on the first ripening stages of the fruit more starch is stored. This stage was used to add enzymes (proteins that help chemical reactions to occur faster) and produce the mixture.

Adriana Ruiz Colorado, a Professor from the Faculty of Mines, explains that, in addition to its potential as fuel, this innovation can be used in the food industry, which produces or uses sweeteners in sodas or in backing.

"The mixture"s composition is based on the cellulose and starch from banana. After enzymatic processes performed in the lab, the substances are changed into something called glucose (which is sweet as sugar). It is important to mention that other compounds are created during the process in lower proportions, but they are eliminated for the mixture to have the necessary quality for human consumption," affirmed the Professor.

Although this research group is a pioneer in the production of a mixture based on lignocellulosic material, in some countries such as United States, Brazil, and even in Colombia, several studies are being carried out using sugarcane bagasse, palm and grass.

"In the US, second generation alcohol is made out of corn cob and grass, that"s to say, from lignocellulosic materials," explained Ruiz.

While the process of patent is finished, the research group is concentrated in purifying the mixture and improving the efficiency of the process using mathematical models in order to improve it.

Correo Electrónico

Correo Electrónico

DNINFOA - SIA

DNINFOA - SIA

Bibliotecas

Bibliotecas

Convocatorias

Convocatorias

Identidad UNAL

Identidad UNAL