Scientists from Universidad Nacional de Colombia in Medellin are part of the few people who are investing in the creation of this material that has become in the panacea for industrial and technological applications, since this material allows technological devices to be more powerful and thinner.

The novelty is that new uses are being created, such as obtaining a material to substitute titanium in human implants and environmentally friendly.

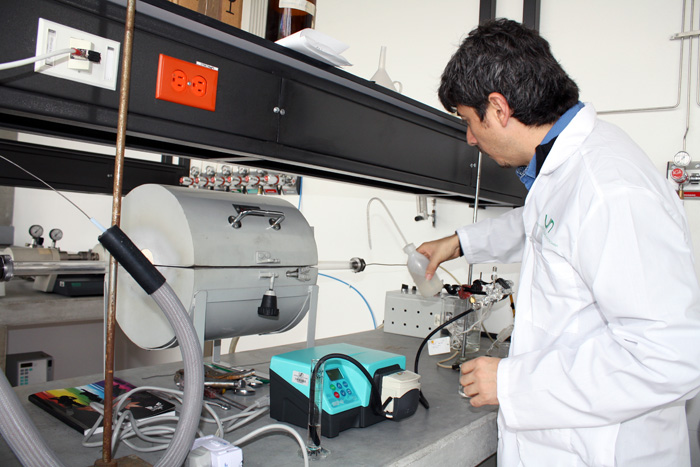

In the characterization laboratories of the Group of Science and Technology of Materials, gas with carbon is used; it is introduced in an oven at high temperatures (between 600 °C and 800 °C). The process is helped by a metallic catalyst (nickel, silver and other depending of the objective), that allows the creation of nanotubes, preventing the formation of amorphous carbon and speeding up chemical reactions that break molecular bond of hydrocarbon. Finally, the carbon encapsulated in gaseous molecules reorganizes in small metallic particles or nanotubes.

The added value of this work performed at the campus is the use of precursors such as ethanol, methane and CO2. With the first, the fabrication of a renewable source is boosted. With the other two, the method is environmentally friendly.

"When I use CO2 from the atmosphere and put it into a reactor, I capture the carbon and condense it as nanotubes; that means, I take carbon from the atmosphere and change it into something solid. If this idea were performed at pilot scale, it would be a useful mechanism to reduce the concentration of green effect gasses," mentioned Germán Sierra Gallego, professor of the School of Materials of the Faculty of Mines.

Applications

These nanotubes are used in different projects. Universidad Nacional de Colombia reinforces pieces of stainless steel to be used as biomaterials in human implants that normally are made of titanium and other expensive alloys. With this invetion, people of limited means would have access to this type of pieces.

Its applications include microelectronics and the modification of the fiction coefficient, with means an increase in the levels of wear resistance due to friction between pieces.

"We have evidence in which carbon natotubes are used as lubricants in dry or liquid surfaces. Fiction coefficient is reduced from 0.45 to 0.15, that means, a third part," asserted the investigator.

Another project aims at improving the properties of aluminum. The idea is reinforcing economical material with nanotubes in order to give them added value. The idea is to go beyond aluminum which is terminally treated, a process that gives it better resistance.

This material is one of the fundamental elements in the industry and the technology of the future.

For reading the complete article please visit

Correo Electrónico

Correo Electrónico

DNINFOA - SIA

DNINFOA - SIA

Bibliotecas

Bibliotecas

Convocatorias

Convocatorias

Identidad UNAL

Identidad UNAL